- Mpa High Pressure

- Flow Rate

- 101-300 L / Min (3)

- 2.2 L / Min (2)

- 2.4l / Min (2)

- 2.5 L / Min (19)

- 2.7l / Min (6)

- 3, 5 L / Min (5)

- 3.5l / Min (3)

- 300l / 79.25gal / H (3)

- 50 L / Min (2)

- 50l / Min (3)

- 59-82 L / Min (3)

- 80l / Min 95l / Min (2)

- 83l / Min (2)

- 85l / Min (3)

- 90l / Min 70l / Min (2)

- 98 L / Min 83l / Min (2)

- Regular (2)

- Standard (2)

- Other (2218)

- Items Included

- Material

- Spray Width

- Suitable For

- Type

- Air Compressor (47)

- Air Compressor Pump (29)

- Air Pump Set (12)

- Airless Sprayer (128)

- Car Washer (7)

- Compressor (5)

- High Pressure (139)

- High-pressure Washer (3)

- Hydraulic (55)

- Nail Gun (2)

- Oil-water Separator (3)

- Pcp Air Compressor (7)

- Piston Compressor (42)

- Pressure Washer (7)

- Pump (2)

- Regular (2)

- Regulator (3)

- Sensor (3)

- Spray Gun (5)

- Vacuum (26)

- Other (1757)

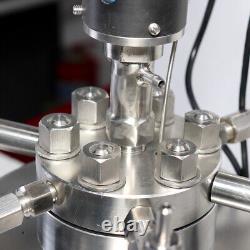

Lab Hydrothermal Synthesis Autoclave Reactor Tabletop High Pressure 22Mpa SS316

Characteristics and Uses: The desktop stainless steel autoclave can be used for: gas-liquid, liquid-liquid, liquid-solid, and other various reaction. The main features of the device are static sealing structure, which can completely solve the leakage problem of stirring, keep the entire medium and mixing parts completely sealed. Therefore, it is more suitable for a variety of flammable, explosive, highly toxic, valuable media and other chemical media with strong penetration.

The product integrates stirring, heating and high-pressure reaction. It is a combination of Mechanical stirring and stainless steel high-pressure reactor for reducing the cost of research unit. The equipment is more versatile and reduce costs for user and widely used in colleges and universities, environmental protection. Lab Hydrothermal Synthesis Autoclave Reactor Tabletop High Pressure 22Mpa SS316. The desktop stainless steel autoclave can be used for: gas-liquid, liquid-liquid, liquid-solid, and other various reaction. The equipment is more versatile and reduce costs for user and widely used in colleges and universities, environmental protection, biochemistry, medical treatment, scientific research and other fields. Small size, simple and reliable structure. LCD displayed srirring speed and temperature, parameter button adjustment, more convenient, more accurate value and more beautiful appearance.It is equipped with a mini DC motor, pressure gauge, explosion-proof device, intake valve, sampling valve and temperature probe, which can easily realize the micro-reaction test. The reaction kettle and heater can be quickly separated, the kettle can be quickly cooled. Temperature and rotational speed are displayed, convenient, quick and controllable. The main sealing port of the autoclave adopts the line contact of the gasket or the tapered surface and the circular arc surface.

By tightening the main nut, they are pressed against each other to achieve a good sealing effect. When tightening the nut, the angle must be symmetrical several times and tightened gradually. The force should be even. Do not allow the lid to tilt to one side to achieve a good sealing effect. Do not exceed the specified tightening torque 40120nm range when tightening the main nut to prevent the sealing surface from being crushed or overloaded.The sealing surface should be specially taken care of. Wipe the upper and lower sealing surfaces with a softer paper or cloth before each installation. Pay special attention not to touch the sealing surface of the kettle body and the lid of the kettle. If reasonably operated, it can be used more than 10,000 times.

Once the sealing surface is broken, it needs to be reworked to achieve good sealing performance. Lift the lid up and down slowly when removing the lid. It is forbidden to collide with the sealing surfaces between the kettle body and the kettle lid.

If the seal type is gasketed tetrafluoro, aluminum pad, copper, asbestos pad, etc. , a good sealing effect can be achieved by tightening the main nut. The temperature of external heating during work is recommended not to exceed 350? /min, can be controlled by PID temperature control system, the cooling rate is? Safety pressure is 22 MPa. The screw is symmetrically pressed after feeding. When the reaction is completed, the kettle body is naturally cooled to room temperature and then open the kettle cover.Do not fill more than 80% in the kettle. If you need to return, please double check to confirm the item not work and contact our customer service representative, let us know the detailed problem and send us some pictures for confirmation. We are a comprehensive company specializing in the research and development, production and sales of lab related equipment.

Company tenet: Respect reputation and contract, provide high-quality and low-cost equipment for serve scientific research. We believe that it is our vision and mission to provide innovative products with best service and competitive price to satisfy you.

Our goal is to make sure that you can find exactly what you are looking for and make it easy for you to place your orders.